How Do You Take Your Crude Oil: Sweet & Light, or Sour & Heavy?

By: Frank Caprio | On: January 30, 2018

Crude oil impacts our life in myriad ways. Every driver on the road is keenly aware of the relatively low gas prices we have been enjoying lately. Remember dire forecasts of $5-a-gallon gasoline? While those predictions may still come to pass, shale oil drilling and Canadian oil sands production have resulted in a huge increase in supply, which has led to lower fuel costs. Today, many discussions about oil prices center on WTI – also known as West Texas Intermediate – which is the grade of oil used in the U.S. to set benchmark pricing. Much of the world benchmarks oil prices using either Brent crude, which is extracted from the North Sea, or Dubai/Oman crude from the Middle East. Although many oil benchmarks exist, why do they each have different costs? Let’s take a quick look at the factors involved in determining the price of a barrel of oil, and how those factors can affect hose and expansion joint selection.

Crude Oil: Light or Heavy, Sweet or Sour

Each grade of crude oil has its own unique characteristics, which subsequently affects its demand in the market. The location of the crude oil and how easily it can be extracted and brought to market is certainly one cost factor. Two additional cost factors that are especially important to refiners are the density of the oil and the amount of sulfur present in it. Oil density is specified using a gravity rating scale implemented by the American Petroleum Institute. The higher the number, the lighter the oil; any liquid with an API gravity higher than 10 is lighter than water.

Each grade of crude oil has its own unique characteristics, which subsequently affects its demand in the market. The location of the crude oil and how easily it can be extracted and brought to market is certainly one cost factor. Two additional cost factors that are especially important to refiners are the density of the oil and the amount of sulfur present in it. Oil density is specified using a gravity rating scale implemented by the American Petroleum Institute. The higher the number, the lighter the oil; any liquid with an API gravity higher than 10 is lighter than water.

Crude oil with an API gravity less than 30 is considered “heavy”, and oil with an API gravity greater than 30 is “light”. Most grades have an API gravity between 10 and 70. Heavier grades of crude are generally less expensive but are more difficult to refine, requiring specialized equipment (catalytic cracking, advanced coking equipment, etc.), and produce a different mix of refined products than those derived from “light” crude. Sulfur is the other important cost factor because refiners must remove excess sulfur in order to prevent it from fouling their refining equipment, and to meet ever more stringent emissions requirements imposed by the government. While crude oil may contain numerous other impurities (heavy metals, waxes, salts, etc.), oil with a high sulfur content is considered “sour” and low-sulfur oil is “sweet”.

What Grades Do Refineries Prefer?

Now that we know the difference between light and heavy, sour and sweet, which grade does a typical refinery prefer? Again, the answer is not so simple. Some refineries are configured to process lighter, sweeter grades of oil, while others have equipment that is better suited to handle heavy, sour crude. In the U.S. gulf coast region, refiners are equipped to process heavier grades of crude, such as has been imported from Mexico, Venezuela, and the Middle East for many years. Alternately, many Canadian refiners traditionally prefer lighter, sweeter grades of oil, which was either produced domestically or imported as Brent crude.

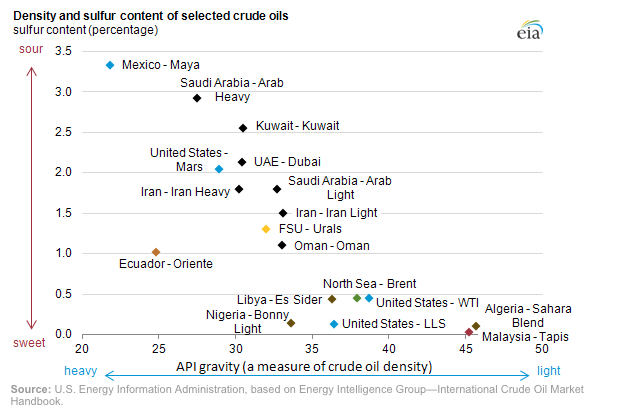

In fact, most refineries are configured to handle a blend of both light and heavy oils (called the “crude slate”) to produce the most desirable and valuable refined products (or “product slate”). This is why refiners must often use crude from several sources in order to achieve their optimal feedstock. Due to new sources of oil recently made available through shale drilling and oil sands extraction, the crude slate is rapidly changing, and many refineries are slow to catch up. Those that have made the necessary upgrades to their facilities are able to process a broader crude slate, meaning they can change their processing operations to accommodate whatever grades are readily available at competitive prices. For example, the sulfur content of crude oil feedstock to U.S. refiners has increased from 0.88% in 1985 to over 1.4% in 2017 (per EIA’s website). At the same time, most of the oil produced from shale formations is relatively light, and is produced in quantities exceeding refiners’ ability to blend it into their crude slate. This is why U.S. drillers celebrated the December 2015 lifting of the ban on crude oil exports, allowing them to export excess sweet crude at a handsome profit. The following chart from the EIA shows different grades of crude available to refiners today:

The lighter, sweeter grades of crude oil command a price premium, as they are easier to process and produce a higher percentage of gasoline than heavier grades, which produce more diesel fuel. Some smaller refineries are specifically designed to take advantage of the plentiful supply of light, sweet crude oil currently available, turning lighter grades of crude into gasoline and other valuable hydrocarbons with only minimal refining. These plants are referred to as hydroskimming refineries or topping refineries, depending on the processes involved.

What Does All of This Mean to Us?

We must know how any given refinery is configured in order to have a better understanding of their needs. Many refineries have their own webpage, describing their capacity, crude slate, and operations, which can be a great resource to consult when trying to get a better understating of their business. Metal hoses and expansion joints are widely used in refineries because they offer a safe, dependable means to transfer hot, sometimes corrosive media that would quickly destroy non-metallic components. Refineries that are configured to process heavy, sour crude have corrosion problems associated with the sulfur present in their process systems. We have seen where 316SS provides added corrosion resistance in these applications. However, severely corrosive applications may require a high-nickel alloy (such as our 276 alloy ChemKing® hose) to resist the sulfides present in sour crude and in the product streams and vapors found in refining and desulfurization processes.

Maintenance turnarounds require literally hundreds of hoses and expansion joints for various applications. Service, safety, and reliability are all key. During planned shutdowns, workdays are hectic, schedules are ever-changing, and hose procurement planning is often an afterthought. We can help projects stay on schedule without compromising safety with our lightning-fast lead times and commitment to quality, ensuring customers get what they want, when they want it. Let our vast experience in refinery applications work for you. Contact us today to discuss ways we can help you provide solutions to any application: sweet, sour, heavy, or light!

Copyright 2018, Hose Master, LLC

All Rights Reserved