TECHNICAL REPORT

Subject: Low Temperature Hose Service

By: Hose Master

Date: July 7, 2016

One of the advantages metal hose has over rubber or plastic hose is its ability to withstand low temperatures. However, it is still necessary to match the assembly components to the anticipated application temperature, otherwise premature failure may occur. For example, low temperature ratings for stainless steels vary depending on the alloy, the applicable standard (ASME, EN, etc.), the manufacturing method (e.g. cast, forged, etc.), and many other factors. Additionally, the low temperature limit for a fabricated metal hose assembly may be dictated by the welder qualifications for the assembler in addition to the alloy specifications. Some metals, particularly ferrous (iron-based) alloys such as carbon steel, are susceptible to losing their normal ductile properties and becoming brittle at relatively moderate temperatures.1

Example: ASTM A53 Type F carbon steel, a common pipe material, is rated for service only down to 20°F.

Fortunately, the yield2 and tensile3 strengths of austenitic4 stainless steels, nickel alloys such as 276, and many copper based alloys such as bronze, significantly increase as the temperature decreases. The material ductility5 decreases, but not sufficiently to preclude their use for most applications.

The fatigue strength of 300-series stainless steels actually increases at lower temperatures. With 300-series stainless steel corrugated metal hose applications, as the temperature drops:

- The strength of the hose increases.

- The resistance of the hose to fatigue fracture initiation increases.

- Fatigue cracks progress through the hose wall at reduced rates from those at ambient temperature.

Please Note: If a customer is requesting hose for “low temperature” service, it is important to obtain the actual minimum operating temperature. The terms “cryogenic” and “absolute zero” may be specified, but these are not sufficient for accurately defining an application:

- “Cryogenic” does not define a temperature. The term is actually rather loose and can vary substantially depending on the source. Definitions generally include -237°F and colder.

- There is a large gap between the temperature of liquid nitrogen, -320°F, and that of the next lower-temperature liquefied gas of importance, liquid hydrogen, which boils at -423° Liquid helium, boiling at -452’F, is the only other cryogen that fills this low-temperature range.

- “Absolute Zero” is –459.67° It a theoretical temperature and cannot actually be achieved.

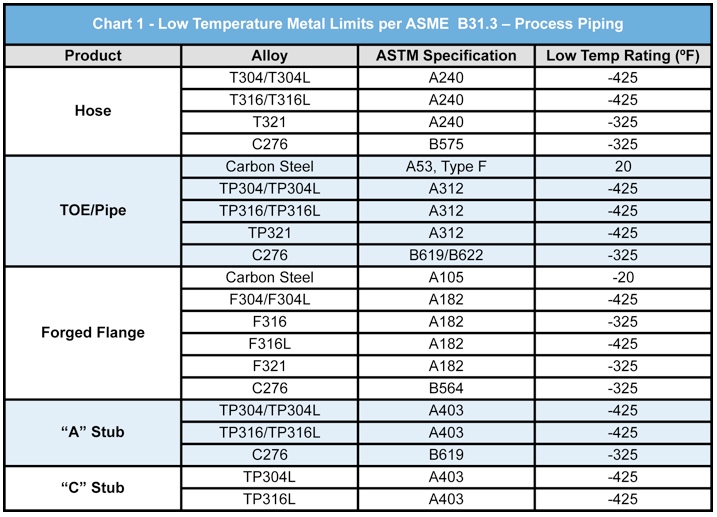

Temperature “ratings” sometimes vary between information sources. For consistency, Hose Master uses the low temperature ratings in ASME B31.3 – Process Piping. (See Chart 1)

To Determine the low temperature limit for an assembly component not listed in Chart 1:

- Determine the specific ASTM standard for the material from which the component is manufactured.

- Refer to ASME 31.3 Table A-1 for the material and specification.

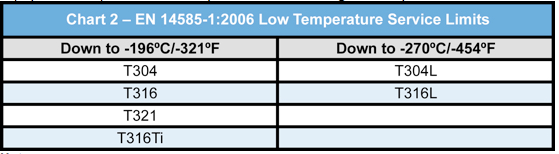

A popular European standard specifies the following low temperature limits for stainless steel hose, braid, and ferrules6.

Notes:

1 The temperature at which the metal becomes brittle is termed the “Ductile ̶ Brittle Transformation Temperature” (DBTT)

2 Yield Strength is the point at which a stressed (deformed) metal will not return to its original shape.

3 Tensile Strength is the maximum amount of pulling stress a metal can accommodate before failure.

4 Austenitic Stainless Steels include 300 series stainless steels (e.g. 304, 316…).

5 Ductility is the ability to form or change the shape of metal.

6 The European Standard BS EN 14585-1:2006 “Pressurized Corrugated Metal Hose Assembly for Pressure Applications, Part 1: Requirements”. Applies to hose, braid and ferrules only. Austenitic Stainless Steel must conform to EN 10028-7 chemistry. (See Chart 2)

NOTE: The data provided is the most current available, and may change without notice. This information is for reference only; contact Hose Master for assistance regarding specific low temperature limits.