Annuflex™

Annuflex™

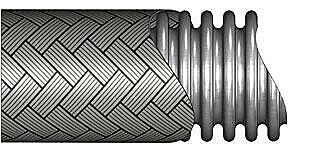

Annuflex™ is the standard of Hose Master’s extensive line of high performance annular corrugated stainless steel hose. Proprietary Stress-Lite™ technology ensures the excellent cycle life of the hose, with minimum effort to flex or bend the hose.

Explanation of Annuflex™ Part Numbers:

AF ____________

Material Code

7 ____________

Braid Code

Material Codes:

4 – T321 Stainless Steel

5 – T316L Stainless Steel

7 – T304L Stainless Steel

Braid Codes:

00 – Unbraided

50 – T304 Single Braid

55 – T304 Double Braid

*T316 Braid available upon request.

Example: AF4750 = T321 Stainless Steel, annular, corrugated metal hose with a single T304 Stainless Steel braid.

| Inside Diameter (in.) | Number of Braids (#) | Outside Diameter (in.) | Static Min. Bend Radius (in.) | Dynamic Min. Bend Radius (in.) | Maximum Working Pressure (psi) | Burst Pressure (psi) | Weight Per Foot (lbs.) |

|---|---|---|---|---|---|---|---|

| 1/4 |

0 1 2 |

0.41 0.47 0.53 |

1.0 | 4.5 |

90 1800 2700 |

n/a 7233 9100 |

0.04 0.11 0.18 |

| 3/8 |

0 1 2 |

0.55 0.61 0.67 |

1.2 | 5.0 |

70 1558 2336 |

n/a 6230 9345 |

0.06 0.16 0.25 |

| 1/2 |

0 1 2 |

0.77 0.83 0.89 |

1.5 | 5.5 |

70 1186 1779 |

n/a 4743 7115 |

0.11 0.22 0.33 |

| 5/8 |

0 1 2 |

0.96 1.02 1.08 |

1.8 | 7.0 |

57 1205 1808 |

n/a 4820 7230 |

0.17 0.33 0.49 |

| 3/4 |

0 1 2 |

1.08 1.14 1.20 |

2.1 | 8.0 |

43 898 1347 |

n/a 3591 5387 |

0.18 0.35 0.53 |

| 1 |

0 1 2 |

1.32 1.39 1.45 |

2.7 | 9.0 |

43 718 1077 |

n/a 2872 4308 |

0.23 0.47 0.71 |

| 1 1/4 |

0 1 2 |

1.75 1.83 1.91 |

3.1 | 10.0 |

43 645 968 |

n/a 2581 3872 |

0.29 0.61 0.93 |

| 1 1/2 |

0 1 2 |

2.08 2.16 2.24 |

3.9 | 11.0 |

28 531 797 |

n/a 2125 3188 |

0.47 0.85 1.23 |

| 2 |

0 1 2 |

2.61 2.69 2.77 |

5.1 | 13.0 |

14 449 674 |

n/a 1797 2696 |

0.59 1.11 1.63 |

| 2 1/2 |

0 1 2 |

3.40 3.50 3.60 |

6.8 | 16.0 |

14 417 626 |

n/a 1669 2504 |

0.84 1.64 2.44 |

| 3 |

0 1 2 |

3.88 3.98 4.08 |

7.8 | 18.0 |

14 346 519 |

n/a 1384 2076 |

1.18 2.06 2.94 |

| 4 |

0 1 2 |

4.96 5.06 5.16 |

9.98 | 22.0 |

14 299 448 |

n/a 1194 1791 |

1.41 2.69 3.97 |

| 5 |

0 1 2 |

6.00 6.12 6.24 |

12.8 | 28.0 |

14 275 412 |

n/a 1099 1649 |

2.18 3.61 5.04 |

| 6 |

0 1 2 |

7.01 7.13 7.25 |

14.8 | 32.0 |

11 210 315 |

n/a 839 1259 |

2.69 4.44 6.19 |

| 8* |

0 1 2 |

9.04 9.32 9.60 |

18.0 | 29.0 |

3 250 360 |

n/a 1000 1446 |

4.88 8.21 11.53 |

| 10* |

0 1 2 |

11.34 11.56 11.78 |

21.0 | 34.0 |

4 175 310 |

n/a 700 1247 |

7.42 11.05 14.67 |

| 12* |

0 1 2 |

13.45 13.73 14.00 |

27.0 | 44.0 |

3 185 325 |

n/a 745 1308 |

11.04 16.71 22.38 |

| 14* |

0 1 2 |

14.50 14.78 15.05 |

31.0 | 68.5 |

3 122 245 |

n/a 488 980 |

10.1 17.37 24.64 |

| 16* |

0 1 2 |

16.50 16.78 17.05 |

36.0 | 70.9 |

2.8 97 193 |

n/a 388 772 |

11.65 18.63 25.62 |

| 18* |

0 1 2 |

19.00 19.31 19.62 |

42.0 | 71.7 |

2.7 94 188 |

n/a 376 752 |

16.66 25.26 33.85 |

| 20* |

0 1 2 |

21.00 21.31 21.62 |

46.0 | 74.8 |

2.5 75 150 |

n/a 300 600 |

19.28 28.05 36.81 |

| 24* |

0 1 2 |

25.00 25.31 25.62 |

55.0 | 85.8 |

2.3 59 118 |

n/a 236 472 |

23.17 32.59 40.09 |

| 30* |

0 1 2 |

31.00 31.31 31.62 |

67.0 | 108.9 |

2.2 43 87 |

n/a 172 348 |

26.19 34.95 43.71 |

*8 through 30 in. diameters are supplied with braided braid

Notes:

- The minimum bend radius is measured from the centerline of the hose

- The working pressure decreases with temperature – see derating factor

- For rapid pressure fluctuations consult the factory

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

-

When to Use Flexible Metal Products

-

Select the Right Hose for Your Application

-

Select the Right Corrugated Metal Hose

-

Select the Right Stripwound Metal Hose