ChlorSafe™

ChlorSafe™

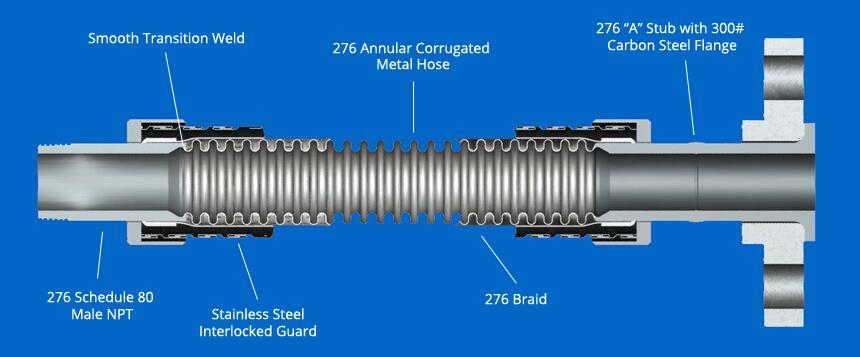

Our chlorine transfer hose assemblies are constructed of alloy 276 and are specifically designed, produced, and tested to meet the strict demands of both wet and dry chlorine transfer applications.

With considerations made for both wet and dry chlorine, these assemblies are the safest available. ChlorSafe™ assemblies are manufactured in compliance with the Chlorine Institute Pamphlet 6, Appendix A, latest edition.

Explanation of ChlorSafe™ Part Numbers:

AF 67____________

Braid Code

Braid Codes:

20 – C276 Single Braid

22 – C276 Double Braid

Example: AF6720 = 276 annular corrugated metal hose with a single C276 Braid.

| Inside Diameter (in.) | Number of Braids (#) | Outside Diameter (in.) | Dynamic Min. Bend Radius (in.) | Maximum Working Pressure (psi) | Burst Pressure (psi) |

|---|---|---|---|---|---|

| 1/2 |

1 2 |

0.83 0.89 |

8.0 | 500 | 2500 |

| 3/4 |

1 2 |

1.22 1.28 |

9.0 | 375 | 1875 |

| 1 |

1 2 |

1.53 1.59 |

10.0 | 375 | 1875 |

| 1 1/2 |

1 2 |

2.16 2.24 |

11.0 | 375 | 1875 |

| 2 |

1 2 |

2.69 2.77 |

13.0 | 375 | 1875 |

Notes:

- The minimum bend radius is measured from the center-line of the hose

- Per Chlorine Institute specifications, pressure ratings represent a 5:1 safety factor

- For pressures in excess of Chlorine Institute standards, please consult the factory

Chlorsafe™ Features

- Hose Master’s proprietary manufacturing process reduces residual stress and produces the most flexible chlorine transfer hose available

- ChlorSafe’s™ all metal construction makes it fire resistant

- Proprietary welding techniques provide a smooth transition from hose to fitting with no gaps or crevices to entrap contaminants

- All welds are argon-purged to eliminate oxidation

Chlorsafe™ Specifications

- All wetted surfaces and the braid are made from UNS N10276 (referred to as either C276 or 276 alloy) which has the highest chemical resistance rating for both dry and wet chlorine 1

- Every assembly is helium mass spectrometer leak tested to at least 5.0 x 10-6 std cc/sec.

- Each assembly is covered by a stainless steel interlocked metal hose for maximum durability

- All assemblies strength tested to twice maximum allowable working pressure

1 Kenneth M. Pruett, Chemical Resistance Guide for Metals and Alloys: A Guide to Chemical Resistance of Metals and Alloys (Derby: Compass Publications, 1995), 93.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

-

When to Use Flexible Metal Products

-

Select the Right Hose for Your Application

-

Select the Right Corrugated Metal Hose

-

Select the Right Stripwound Metal Hose