Services

Hose Master is about more than great flexible metal products. We complement our product portfolio with an array of value-added services, to make sure customers receive exactly what they need to keep their operations running smoothly.

PRE-SALE

Application Expertise. Safe and reliable use of metal hose and expansion joints requires optimizing the product to the rigors of each application. This all starts with acquiring a deep understanding of each application so that we can make sure customers receive the best solution to match their needs. Hose Master offers unparalleled support in engineering, inside sales, and field assistance to aid in designing, providing, and supporting metal hose and expansion joints that meet specific application requirements.

Expansion Joint Design Services. To complement our pre-engineered expansion joint portfolio, we offer custom-designed expansion joints by leveraging our technical expertise and innovation. Using the winning formula that made us the industry leader for engineered metal hose and assemblies, Hose Master engineers work hand-in-hand with customers to understand the application and the environment, then design and model a product that is tuned specifically for the application.

Hose Master University. Hose Master offers Hose Master University to customers interested in learning about metal hose and expansion joints and the fundamentals of industry, applications, and sales. Beginner and advanced courses are available.

MANUFACTURING

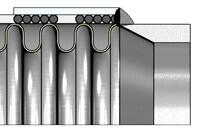

Specialized Attachment Techniques. In addition to industry standard welding techniques, Hose Master also offers several other attachment techniques for use in specialized applications. These include: Half-corrugation, Smooth transition, and Braid-over construction. Here are details on these attachment techniques.

Testing Services. All of our corrugated products are leak tested prior to shipment. Other testing options include: hydrostatic testing, high-pressure testing, dye penetrant testing, and helium mass spectrometer testing. Learn more about testing services.

Packaging. All assemblies are shipped with protectors over threads and flange faces, and spacer bars are installed on shorter double-flanged assemblies to prevent compression. Additional packaging options are available to suit customer requirements, including crating, plastic bagging, labeling, and custom fitting protectors.

POST-SALE

After Hours Emergency Service. Industry doesn’t run on a 9 to 5 schedule. Neither do we. Hose Master’s After Hours Emergency Service for metal hose and expansion joints provides our customers with expedited response for critical and time sensitive situations that arise beyond normal business hours. This service is backed by all four Hose Master facilities – Cleveland, Houston, Atlanta, and Reno. Call 800-221-2319 to reach us.

Expansion Joint Rebuild. Using customer-provided components from an expansion joint removed from service, Hose Master can replace bellows and often reuse pre-existing pipe and fittings. This offers a cost-effective option when dealing with very large diameter expansion joints and special designs. Hose Master can also reverse-engineer the product for its specified application or evaluate the parts that are being replaced in our laboratory to determine the cause of failure. Backed with this knowledge, Hose Master’s team of engineers and ASME IX certified welders can design and make any necessary changes to the expansion joint to enhance its performance and extend its service life.

Product & Failure Analysis. A key to permanently solving any tough flexible metal application is to accurately identify the root cause(s) of past failure modes of products removed from service. Hose Master’s in-house product and failure analysis lab can identify various failure modes, whether a result of fatigue, corrosion, deformation, or from a host of other possible causes. Hose Master is the only metal hose and expansion joint manufacturer in North America that offers in-house failure analyses and reverse engineering as a no-charge service to its distributor partners.

-

When to Use Flexible Metal Products

-

Select the Right Hose for Your Application

-

Select the Right Corrugated Metal Hose

-

Select the Right Stripwound Metal Hose