Hose Master is a premier manufacturer of metal bellows and metal expansion joints.

Expansion Joint Catalog

We have inventory in stock, readily available to meet your needs. We also offer a comprehensive range of pre-engineered expansion joints, backed by our extensive technical expertise and innovative approach. For those seeking a more tailored solution, we provide custom-designed expansion joints, crafted to address your unique specifications. Using the winning formula that made us the industry leader for metal hose, Hose Master provides the same superior engineering and precisely controlled manufacturing processes with our expansion joints.

Engineering & Manufacturing. At the heart of Hose Master’s success is technical expertise. Proprietary equipment, designed and built in-house, allows us to go beyond ordinary products and deliver superior, value-engineered products. Our skilled engineers are ready to assist you in designing metal expansion joints for the most demanding applications.

Quality Assurance. Delivering the highest quality products is a guiding principle at Hose Master. Designs conform to EJMA and ASME Section VIII, meeting the requirements of the piping, boiler and pressure codes – B31.1 and B31.3. This certification applies to the scope of activity related to the fabrication and assembly of pressure piping, which means our engineering and production teams can design systems in accordance with the rules of the ASME Boiler and Pressure Vessel Code. This certification gives Hose Master the “U”, “PP” and “R” Stamps for expansion joints. Customer specifications can be verified through Finite Element Analysis (FEA), or 3D CAD modeling. Expansion joint test options include pneumatic, hydrostatic, high-pressure gas, or liquid penetrant methods, as well as helium mass spectrometry and radiography.

Product & Failure Analysis. A key to permanently solving any tough metal expansion joint application is to accurately identify the root cause(s) of past failure modes of products removed from service. Hose Master’s in-house product and failure analysis lab can identify various failure modes, whether a result of fatigue, corrosion, deformation, or from a host of other possible causes. Hose Master is the only metal hose and expansion joint manufacturer in North America that offers in-house failure analyses and reverse engineering as a no-charge service to its distributor partners.

Service. With 90+ ASME IX Certified welders and a comprehensive material stocking program, Hose Master provides the exceptional service our industry demands. In addition to providing the best standard delivery lead-time, Hose Master offers our After Hours Emergency Service for hose and expansion joints, providing customers an expedited response for critical and time-sensitive situations that arise beyond normal business hours.

If you have an expansion joint application and are in need of assistance please contact us. Our skilled team of experts can help provide the right solution and answer any questions.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

-

US

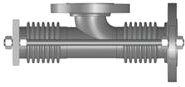

Unrestrained Single

-

LS

Limit Single

-

TS

Tied Single

-

HS

Hinged Single

-

SHS

Slotted Hinged Single

-

GS

Gimbaled Single

-

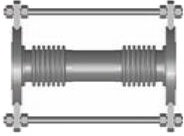

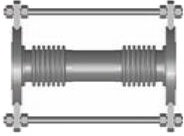

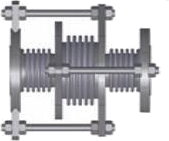

UU

Unrestrained Universal

-

TU

Tied Universal

-

PBS

Pressure Balanced, Elbow, Single

-

PBU

Pressure Balanced, Elbow, Universal

-

PBI

Pressure Balanced In-Line

-

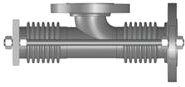

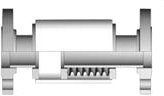

EPS

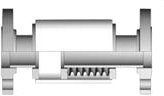

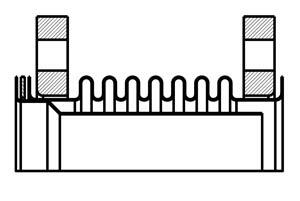

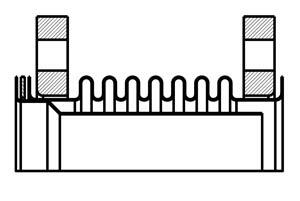

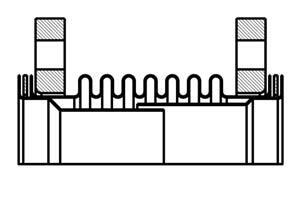

Externally Pressurized Single

-

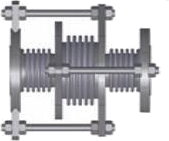

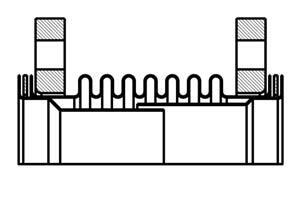

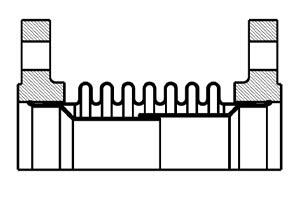

EPD

Externally Pressurized Dual

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

-

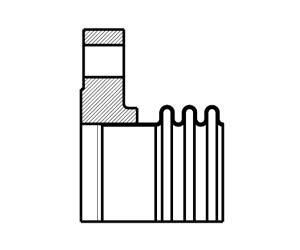

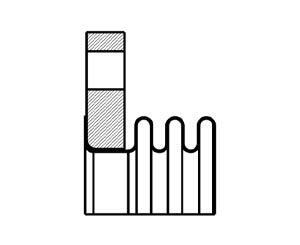

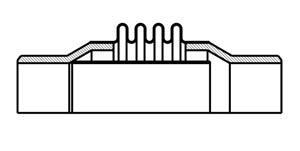

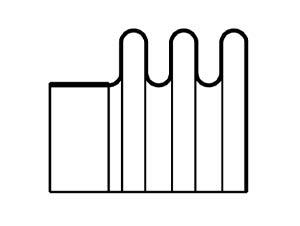

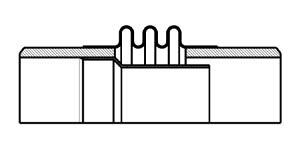

BB – Banded Bellows

Ideal for slipping over pipe and welding in place.

-

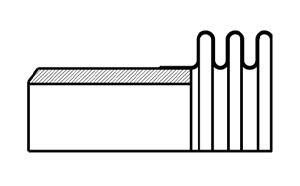

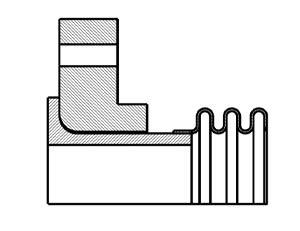

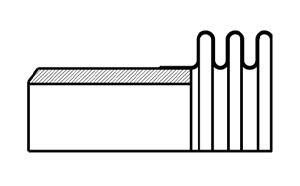

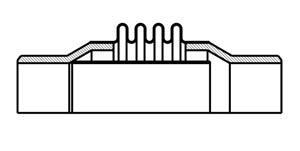

WE – Welded End

Beveled to facilitate pipe-to-pipe welding. Most common end connection.

-

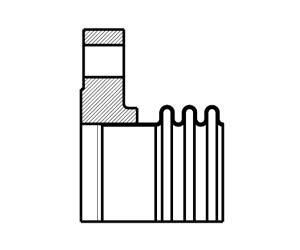

FF – Fixed Flange

Recommended for ease of replacement. Requires accurate flange hole alignment.

-

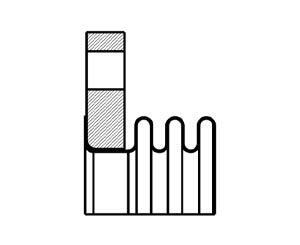

VF – Vanstone Flange

Economical solution for piping systems with misaligned bolt holes.

-

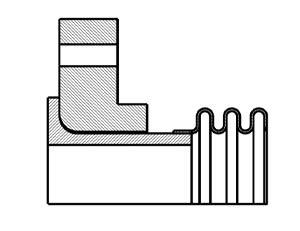

LJ – Lap-Joint Flange

Commonly used when vanstone flanges are not an option.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

-

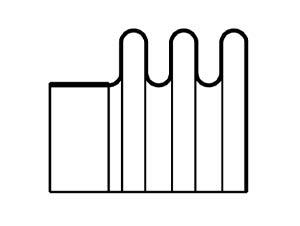

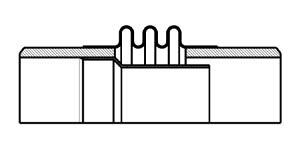

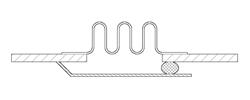

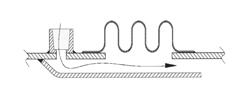

SW – Single Welded Liner

Most common type of internal liner. Maximum durability.

-

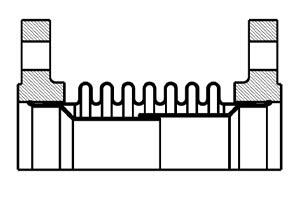

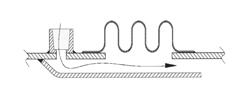

TW – Telescoping Welded Liner

For large axial movements.

-

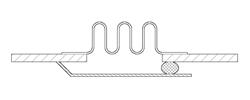

FW – Flush Welded Liner

No protrusion into flow-stream. Minimal pressure drop. Recommended for refactory-lined pipe.

-

SD – Single Drop-In Liner

Can be removed and cleaned.

-

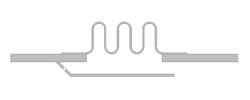

TD – Telescoping Drop-In Liner

For large axial movements. Can be removed and cleaned.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

Comparison of Ratings, Features, and Available Options

| EJ Styles |

Relative Movement Capability |

Relative Spring Forces |

Pressure Thrust on Piping System |

Available Features |

| Axial |

Angular |

Lateral |

Axial |

Angular |

Lateral |

Internal Flow Liner Types |

External Cover |

Redundant Ply Design |

End Connection Types |

US

Unrestrained Single |

↔ |

↔ |

↓ |

↔ |

↔ |

↑ |

YES |

SW

, TW

, FW

, SD

, TD

|

YES |

YES |

BB

, WE

, FF

, VF

, LJ

|

LS

Limit Single

|

↔ |

↔ |

↓ |

↔ |

↔ |

↑ |

YES |

SW,

TW,

, FW

, SD

, TD

|

YES |

YES |

BB,

WE

, FF

, VF

, LJ

|

TS

Tied Single

|

— |

— |

↓ |

— |

— |

↑ |

NO |

SW

, TW

, FW

, SD

, TD

|

YES |

YES |

BB

, WE

, FF

, VF

, LJ

|

HS

Hinged Single

|

— |

↔ |

— |

— |

↔ |

— |

NO |

SW, TW, FW, SD, TD |

YES |

YES |

WE, FF, VF, LJ |

SHS

Slotted Hinged Single

|

↔ |

↔ |

— |

↔ |

↔ |

— |

YES |

SW

, TW

, FW

, SD

, TD

|

YES |

YES |

WE

, FF

, VF

, LJ

|

GS

Gimbaled Single

|

— |

↔ |

— |

— |

↔ |

— |

NO |

SW

, TW

, FW

, SD

, TD

|

YES |

YES |

WE

, FF

, VF

, LJ

|

UU

Unrestrained Universal

|

↔ |

↔ |

↑ |

↔ |

↔ |

↓ |

YES |

SW

, TW

, FW

, SD

, TD

|

YES |

YES |

BB

, WE

, FF

, VF

, LJ

|

TU

Tied Universal

|

— |

— |

↑ |

— |

— |

↓ |

NO |

SW

, TW

, FW

, SD

, TD

|

YES |

YES |

WE

, FF

, VF

, LJ

|

PBS

Pressure-Balanced, Elbow, Single

|

↔ |

— |

↔ |

↔ |

↔ |

↑ |

NO |

SW

, TW

, FW

, SD

, TD

|

YES |

YES |

WE

, FF

, VF

, LJ

|

PBU

Pressure-Balanced, Elbow, Universal

|

↔ |

— |

↑ |

↔ |

↔ |

↓ |

NO |

SW

, TW

, FW

, SD

, TD

|

YES |

YES |

WE

, FF

, VF

, LJ

|

PBI

Pressure-Balanced, In-Line

|

↔ |

— |

— |

↔ |

— |

— |

NO |

SW

, TW

, FW

, SD

, TD

|

YES |

YES |

WE

, FF

, VF

, LJ

|

EPS

Externally-Pressurized Single

|

↑ |

— |

— |

↔ |

— |

— |

YES |

FW

|

INCL |

YES |

WE

, FF

, LJ

|

EPD

Externally-Pressurized Dual

|

↑ |

— |

— |

↔ |

— |

— |

YES |

FW

|

INCL |

YES |

WE

, FF

, LJ

|

Legend:

↑ Higher

↔ Moderate

↓ Lower

— Non Applicable

Options

-

Purge Ports

-

Packed Bellows

-

Self-Draining Liner

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

Expansion Joint Rebuild. Using customer-provided components from an expansion joint removed from service, Hose Master can replace bellows and often reuse pre-existing pipe and fittings. This offers a cost-effective option when dealing with very large diameter expansion joints and special designs. Hose Master can also reverse- engineer the product for its specified application or evaluate the parts that are being replaced in our laboratory to determine the cause of failure. Backed with this knowledge, Hose Master’s team of engineers and ASME IX certified welders can design and make any necessary changes to the expansion joint to enhance its performance and extend its service life.

Contact Hose Master for additional information.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.