Hose Master is the leading manufacturer of petroleum flex connectors. Unique design and production capabilities yield the most innovative products available. Hose Master’s unwavering commitment to quality means that these products are right the first time, guaranteed!

Hose Master’s quality commitment doesn’t stop with 100% testing of each connector. Our customer service representatives and production staff have the same goal: to provide you with the product you need, when you need it.

Our FireShield and FireShield QuickClamp petroleum flex connectors are easy to install and safe to use. Click on these links for technical information and product drawings. Each comes with installation and handling instructions.

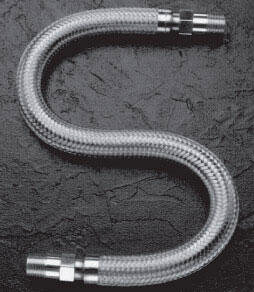

FireShield connectors are the safest, longest lasting, and most flexible metal hose connectors manufactured today. Our unique processes minimize residual stress points created in the hose during the manufacturing process. Our proprietary tube seam weld technology resists aromatic vapor permeation, and our ASME certified welders follow specified procedures to insure the strongest fitting attachments.

Hose Master’s extensive array of available end fittings offer the quickest and most cost-effective solutions for connecting fiberglass or flexible pipe to the submersible pump and shear valve. Hose Master’s FireShield connectors minimize threaded connections, which means fewer leak points and reduced installation time and labor.

FireShield connectors meet all specifications for aboveground and underground piping applications, and comply with NFPA and UFC codes. They are rated for full vacuum and are available with BSPP and BSPT threaded fittings. Connectors are designed to accept approved secondary containment systems.

Premium product, first-rate service and competitive pricing! It’s easy to see why Hose Master is the industry-preferred manufacturer of flexible connectors.

Hose Master’s FireShield connectors are the safest, longest lasting, and most flexible metal hose connectors manufactured today. Hose Master’s unique process makes the difference by minimizing residual stress points created in the hose during the manufacturing process. Hose Master’s proprietary tube seam weld technology resists aromatic vapor permeation and Hose Master’s precise ASME certified welders follow specified procedures to insure the strongest fitting attachments.

Hose Master’s extensive array of available end fittings offer the quickest and most cost-effective solutions for connecting fiberglass or flexible pipe to the submersible pump and shear valve. Hose Master’s FireShield connectors minimize threaded connections, which means fewer leak points and reduced installation time and labor.

Hose Master’s FireShield connectors meet all specifications for aboveground and underground piping applications, and comply with NFPA and UFC codes. They are rated for full vacuum and are available with BSPP and BSPT threaded fittings. Connectors are designed to accept approved secondary containment systems.

Downloadable Drawings

Drawings for these connectors are available below for immediate download in PDF format (IGS format available upon request). Simply click the type of connector you are looking for. All diameters and lengths are included in the PDF files.

FSMM - Male x Male

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 3/4 |

150 |

1-3/4 |

12, 15, 18, 24, 30 |

PDF |

| 1 |

150 |

4 |

12, 15, 18, 24, 30 |

PDF |

| 1-1/2 |

150 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

150 |

6 |

12, 15, 18, 24, 30 |

PDF |

| 3 |

150 |

9 |

12, 15, 18, 24, 30 |

PDF |

FSMF - Male x 2" Female

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

150 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

150 |

6 |

12, 15, 18, 24, 30 |

PDF |

FSMS - Male x Male Swivel

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

50 |

6 |

12, 15, 18, 24, 30 |

PDF |

FSFS - 2" Female x Male Swivel

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

50 |

6 |

12, 15, 18, 24, 30 |

PDF |

FSM2M - 1-1/2" Male x 2" Male

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

150 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

FSMSE - Male x 90 deg Male Swivel

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

50 |

6 |

12, 15, 18, 24, 30 |

PDF |

FSSME - Male Swivel x 90 deg Male

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

50 |

6 |

12, 15, 18, 24, 30 |

PDF |

FSSSE - Male Swivel x 90 deg Male Swivel

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

50 |

6 |

12, 15, 18, 24, 30 |

PDF |

FSSWE - Male Swivel x 90 deg Female Swivel

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

50 |

6 |

12, 15, 18, 24, 30 |

PDF |

FSS2WE - Male Swivel x 2" 90 deg Female Swivel

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

FSMU - Male x Union

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 3 |

50 |

9 |

12, 15, 18, 24, 30 |

PDF |

FSUU - Union x Union

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 3 |

50 |

9 |

12, 15, 18, 24, 30 |

PDF |

*Select flex connectors are available with 100% stainless steel construction for even wider compatibility with evolving fuel blends. Where available – Customers may indicate their preference for a 100% stainless flex connector for qualifying constructions by adding a “-SS” suffix to the part number at no additional charge.

These products highlight our most commonly purchased connectors. As a manufacturer dedicated to solving all of your hose requirements, we have other models available. Hose Master’s trained technical staff will also work with you to design and manufacture custom-built connectors. Please contact our customer service team at 800-221-2319 for further details.

Accessories

-

Swivel Adaptor

Part Number: ACSWA

Hose Master’s plated swivel adapter converts the integral hex male to a swivel end. This unique adapter creates a positive metal-to-metal seal when used with Hose Master’s exclusive 30° chamfered hex male fitting. This swivel adapter facilitates installation and is only compatible with Hose Master’s FireShield or FireShield QuickClamp connectors.

-

Anode

Part Number: ACANO

Hose Master’s underground connectors, used with our anode, comply with EPA regulations for buried metal components. Our easily monitored system also meets NACE RP-01-69 standards for cathodic protection.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

FireShield QuickClamp assemblies make tight flex connector installations as easy as possible. Offered with a multitude of end connections (including FRP fittings) and custom hose lengths, FireShield QuickClamp assemblies offer installers the ability to fasten one or both ends of a connector within a piping system with minimal use of tools – eliminating timely labor costs and increasing profits.

Downloadable Drawings

Drawings for these connectors are available below for immediate download in PDF format (IGS format available upon request). All inventoried connectors include a male adapter (as shown in the drawings) but are available with many different accessories upon request. Simply click the type of connector you are looking for. All diameters and lengths are included in the PDF files.

FSQM - Hex Male x QuickClamp Hex Male

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

50 |

6 |

12, 15, 18, 24, 30 |

PDF |

| 3* |

50 |

9 |

12, 15, 18, 24, 30 |

PDF |

FSQ2M - 2" Male x QuickClamp Hex Male

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

18, 24, 30 |

PDF |

FSQF - 2" Female x QuickClamp Hex Male

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

50 |

6 |

12, 15, 18, 24, 30 |

PDF |

FSQQ - QuickClamp Hex Male x QuickClamp Hex Male

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

12, 15, 18, 24, 30 |

PDF |

| 2 |

50 |

6 |

12, 15, 18, 24, 30 |

PDF |

| 3 |

50 |

9 |

15, 18, 24, 30 |

PDF |

FSQSE - 90° Male Swivel x QuickClamp Hex Male

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

18, 24, 30 |

PDF |

| 2 |

50 |

6 |

18, 24, 30 |

PDF |

FSQT - QuickClamp Tee x QuickClamp Hex Male

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

18, 24, 30 |

PDF |

| 2 |

50 |

6 |

18, 24, 30 |

PDF |

FSQWE - 90° Female Swivel x QuickClamp Hex Male

| Hose Diameter (inches) |

Working Pressure (p.s.i.) |

Minimum Bend Radius (inches) |

Standard Lengths (inches) |

Drawings

(all sizes) |

| 1-1/2 |

50 |

4-1/2 |

18, 24, 30 |

PDF |

| 2 |

50 |

6 |

18, 24, 30 |

PDF |

Accessories

-

ACQQT 3-way QuickClamp Tee

2″ & 3″ sizes

Stainless steel construction

-

ACQGT QuickClamp by Female Glue Pipe Tee (accessory only)

2″ & 3″

sizes Stainless steel construction

In addition to standard QuickClamp flex connectors, Hose Master offers accessory components to easily interchange and install flex connectors with a variety of end connection options.

QuickClamp accessory items feature a stainless steel construction ensuring compatibility with the widest range of fuels including gasoline, gasoline-ethanol blends, ethanol, diesel, and biofuels.

-

ACQM Hex Male

Available Sizes:

1-1/2, 2, & 3″

-

ACQF Hex Female

Available Sizes:

2″

-

ACQME 90° Male

Available Sizes:

1-1/2 & 2″

-

ACQFE 90° Female

Available Sizes:

2″

-

ACQQE 90° Flange

Available Sizes:

2″

-

ACQG Female Glue Pipe

Available Sizes:

2 & 3″

-

ACQGE 90° Female Glue Pipe

Available Sizes:

2 & 3″

-

ACQClamp Clamp

Available Sizes:

1-1/2, 2, & 3

-

ACQSeal Viton Seal

-

ACQCap Cap

Available Sizes:

2 & 3″

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

DEF Flex Connectors are designed and manufactured to meet the specific corrosive environments encountered when transferring Diesel Exhaust Fluid (DEF).

-

Stainless Steel Hex Males Each End

-

Stainless Steel Hex Male x Stainless Steel Female Union

-

Stainless Steel Hex Male x Stainless Steel Hex Male QuickClamp

Hose Master DEF Flex Connectors Feature

- 100% stainless steel construction for optimal corrosion resistance

- Proprietary tube seam weld technology resists oxidation

- Strongest fitting attachments ensured by ASME IX certified welders

- Increased flexibility and service life from Hose Master’s proprietary hydroforming process

- Available in styles as shown left, or with a variety of industrial stainless steel fitting options. Please consult Hose Master inside sales for details

- Connectors are also available in QuickClamp designs (shown left) and include stainless clamp with special peroxide-cured EPDM gasket*

DEF Flex Connector Applications

- Mobile skids

- Above ground totes and storage tanks

- Underground storage tanks

- DEF concentrations recognized by ISO 22241-1 and API DEF Certification standards

* Peroxide-cured EPDM gaskets are NOT interchangeable with standard QuickClamp gaskets

DEF Flex Connector Specifications

Hose

Diameter

(in.) |

Maximum Working Pressure

Hex Males e/e

(p.s.i.) |

Maximum Working Pressure

Hex Male x 150# Hex Female Union

(p.s.i.) |

Maximum Working Pressure

Hex Male x 150# Hex Female Union

(p.s.i.) |

Minimum

Connector

Bend Radius (in.) |

Standard

Connector

Lengths (in.) |

| 3/4 |

898 |

300 |

50 |

2.1 |

12, 18, 24 |

| 1 |

718 |

300 |

50 |

2.7 |

12, 18, 24 |

| 1 1/2 |

531 |

300 |

50 |

3.9 |

12, 18, 24 |

| 2 |

449 |

300 |

50 |

5.1 |

12, 18, 24 |

Notes:

- Other sizes, lengths and stainless end connections are available upon request.

- FireShield connectors are not recommended for DEF service and do not carry UL-approval for that application

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

Hose Specifications

| Specifications |

UL / ULC |

| Hose Diameter (inches) |

3/4 |

1 |

1 1/2 |

2 |

3 |

| Number of Braids |

1 |

1 |

1 |

1 |

1 |

| Braid Alloy |

300 Series Stainless |

300 Series Stainless |

300 Series Stainless |

300 Series Stainless |

300 Series Stainless |

| Hose Material |

300 Series Stainless |

300 Series Stainless |

300 Series Stainless |

300 Series Stainless |

300 Series Stainless |

| Working Pressure (psi) [1] |

150 |

150 |

150 |

150 |

150 |

| Burst Pressure (psi) |

600 |

600 |

600 |

600 |

600 |

| Minimum Bend Radius (inches) [2] |

1.7 |

4.0 |

4.5 |

6.0 |

9.0 |

| Minimum Length for 90° Bend (inches) |

12 |

16 |

18 |

24 |

28 |

- The working pressure is rated at ambient temperatures. Working pressure changes to 50 psi when using a FireShield integral hex swivel fitting or QuickClamp coupling.

- The minimum bend radius is measured from the centerline of the hose.

Fitting Specifications

| Fitting Size (inches) |

Fitting Description |

Thread Size (inches) |

Hex Size (inches) |

| 1 1/2 |

Hex Male – Carbon Steel |

1 1/2 x 11 1/2 |

1.94 |

| 2 |

Hex Male – Carbon Steel |

2 x 11 1/2 |

2.38 |

| 3 |

Hex Male – Carbon Steel |

3 x 8 |

4.00 |

| 3/4 |

Hex Male – Stainless Steel |

3/4 x 14 |

1.06 |

| 1 |

Hex Male – Stainless Steel |

1 x 11 1/2 |

1.38 |

| 1 1/2 |

Hex Male – Stainless Steel |

1 1/2 x 11 1/2 |

2.00 |

| 2 |

Hex Male – Stainless Steel |

2 x 11 1/2 |

2.50 |

| 2 |

Hex Female – Carbon Steel |

2 x 11 1/2 |

2.63 |

| 2 |

Hex Female – Stainless Steel |

2 x 11 1/2 |

2.61 |

| 1 1/2 |

Male Swivel – Carbon Steel |

1 1/2 x 11 1/2 |

1.94 |

| 2 |

Male Swivel – Carbon Steel |

2 x 11 1/2 |

2.38 |

| 1 1/2 |

Female Swivel – Carbon Steel |

1 1/2 x 11 1/2 |

1.94 |

| 2 |

Female Swivel – Carbon Steel |

2 x 11 1/2 |

2.38 |

| 3 |

Female Union – Carbon Steel |

3 x 8 |

5.75 |

| 3/4 |

Female Union – Stainless Steel |

3/4 x 14 |

2.31 |

| 1 |

Female Union – Stainless Steel |

1 x 11 1/2 |

2.42 |

| 1 1/2 |

Female Union – Stainless Steel |

1 1/2 x 11 1/2 |

3.00 |

| 2 |

Female Union – Stainless Steel |

2 x 11 1/2 |

3.50 |

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.

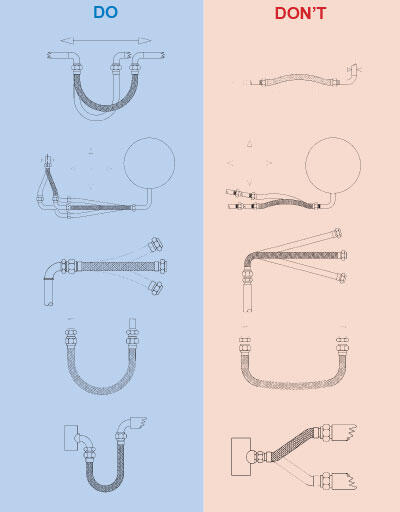

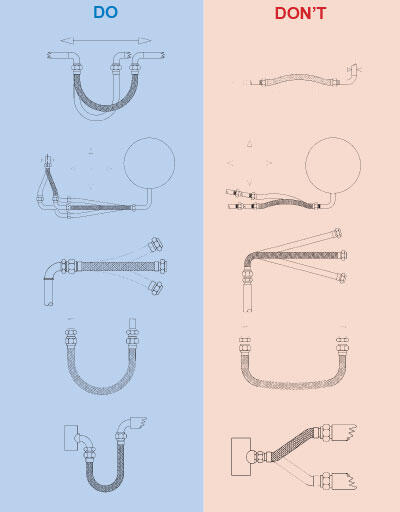

- DO design the installation to allow for all movement (ground, vibration, etc.) after the installation.

- DO keep the hose free from all objects and debris.

- DO measure to ensure proper length of connector has been selected.

- DO handle and store the connectors carefully before an installation.

- DO follow all printed instructions included with the connectors.

- DO note the minimum bend radius as specified.

- DO install flexible connectors so that the bend is as close to the center of the connector as possible.

- DO keep the painted lay line straight and on the centerline of the connector.

- DO use a wrench only on the hex flats.

- DO use the manufacturer’s recommended cathodic protection system or dielectric isolation boot.

- DO check for leaks before covering the installation.

- DON'T use a wrench or any other tool on the hose or braid collar.

- DON'T twist or torque the flex connector.

- DON'T over-bend a flexible connector beyond its minimum bend radius.

- DON'T install a flexible connector with the bend next to the end fittings.

- DON'T attempt to stretch or compress a flexible connector to fit an installation, or allow connector to stretch or compress during use.

- DON'T restrict flexibility by allowing a connector to come into contact with other components or equipment during an installation or during use.

- DON'T expose connector to damage or corrosives during storage, installation or use. Groundwater, road salt, soil, etc. are or may contain corrosives. If necessary use a cover or boot to protect the connector.

- DON'T attempt to reuse a flex connector once it has been installed.

Hose Master places emphasis on continual improvements within our manufacturing processes, product offering and services. Hose Master reserves the right to make changes without further notice to any products contained herein.